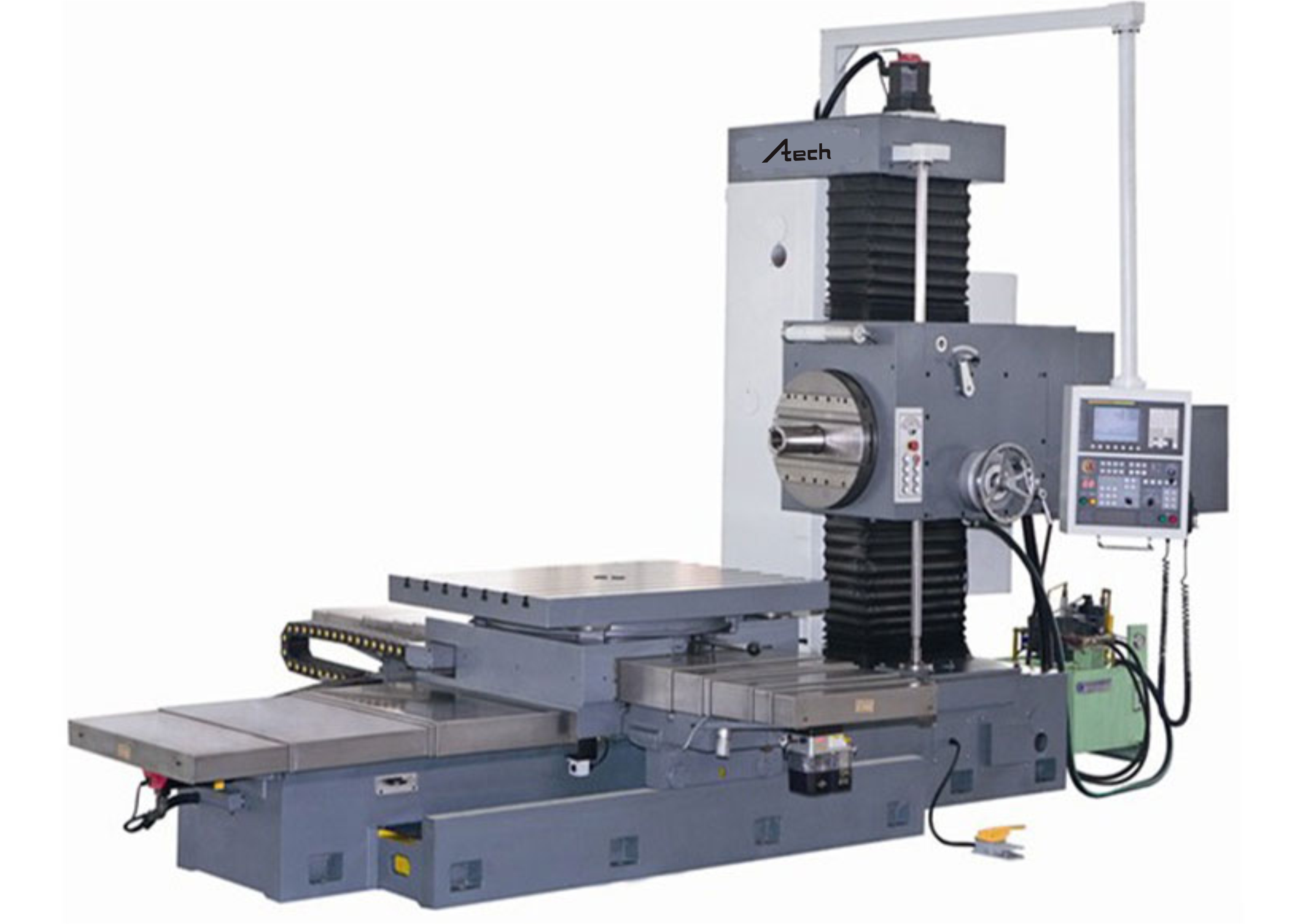

Description

Features

- This machine equipped with a single column, side hung box, four-point positioning worktable, manual rotation (optional Hirth CNC turret 360×1 °indexing).

- X, Y, Z axis controlled by CNC system, could realize simultaneous motion.

- Boring axis’ flexible and axis of facing head are controlled by servo motor, can realize automatic processing

- X, Y, Z axis with rectangular sliding guide .Teflon plastic paste process, shock absorption, and high precision

- The spindle box with counterweight balance, spindle and axis of facing head are controlled by AC servo motor.

Specification

| Max. load of worktable | 2500kg |

| Table size | 1320*1010mm |

| Max. allowable torque on spindle | 1100N.m |

| Max. allowable torque on facing head tool holder | 1100N.m |

| Max. allowable axial feed force on spindle | 13000N |

| Spindle speed step | No step |

| speed step of facing head | No step |

| Spindle speed range | 12-1100r/min |

| Facing head speed range | 4-130r/min |

| Rapid feed speed of spindle | 3600mm/min |

| rapid feed speed of facing head radial tool holder | 1180mm/min |

| Spindle diameter | 110mm |

| Max. distance from spindle nose to table surface | 905mm |

| Min. distance from spindle nose to table surface | 5mm |

| Vertical travel of headstock | 900mm |

| Spindle axial travel | 550 mm |

| radial travel of facing head tool holder | 160 mm |

| Longitudinal travel of table | 1350 mm |

| Cross travel of table | 1250 mm |

| Max. boring diameter of spindle | φ240 mm |

| Max. diameter of facing head tool holder | φ630 mm |

| Max. drilling diameter | φ50 mm |

| Spindle taper | BT50 |

| Main motor power | 11/15kW |

| Rapid feed speed of X,Y,Z | 5000mm/min |

| positioning accuracy of coordinate | X,Z:0.04 mm Y:0.032mm |

| positioning accuracy | 0.02/500mm |

| Repeat positioning accuracy | 0.014/500 |

| Overall dimension(L*W*H) | 5375×2995×3035 mm |

| Net. weight | 12300kg |

Tersedia juga model lain.

Untuk Info Harga Silahkan Hubungi 0858-7630-0414 (Fast respon)